Mooring

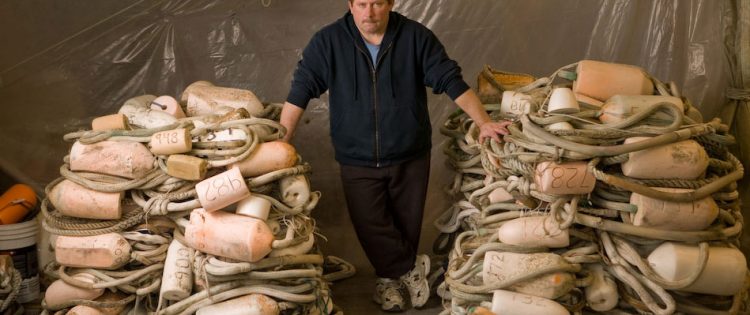

Burr Brothers installs, inspects, and repairs moorings in and around Sippican Harbor, Marion, MA. We fabricate pennants specific to the vessel and anticipated conditions. Our store sells all things for moorings, ie pick up sticks, floats, line, hardware, etc…

Burr Brothers installs, inspects, and repairs moorings in and around Sippican Harbor, Marion, MA. We fabricate pennants specific to the vessel and anticipated conditions. Our store sells all things for moorings, ie pick up sticks, floats, line, hardware, etc…

Notes from Scott –

For many years there was little advancement in the technology of mooring systems. In fact we have had to be very careful about the quality of the popular mushroom anchor. Certain poor models have smaller eyes that wear out quickly and shorter, lighter shanks that allow the anchor to stand up much easier. Once the shank stands up off the bottom, the chain can now wrap around the shank, depriving the mooring of the much needed scope that is critical to its holding power. The shortened scope also greatly increases the stress on the pennant where it passes through the boats’ chock. Even a properly set mushroom can still have its chain wrapped around the dish rather then the shank.

The recently introduced “pyramid” style anchor, in my opinion, offers only a slight improvement over the mushroom anchor. Although effective in soft mud, their short shank still allows for some chain wrapping and their inability to penetrate a hard bottom, to me, rules them out as an “all around” successful alternative to the mushroom anchor.

Until now, the dead weight or block style anchor has been the best solution to these problems. However they are not without their flaws. Cement and concrete lose about a third of their weight once submerged so they need to be at least four times heavier then a mushroom. If the suction that they partly rely on for their holding power is broken, they become less effective. They also don’t penetrate well on hard bottoms and can be as menacing to your keel as a rock when used in shallow water.

In 1997, The Town of Marion passed a mandate requiring that all boats 25 feet or longer be moored with an embedment style anchor. This style anchor, used in much heavier applications for years, has recently been adapted for use as a pleasure craft mooring. Commonly referred to as an “auger” or “helix”, it is screwed into the bottom to an average depth of 10 to 15 feet much like a screw into wood. The machine used to install the anchor measures the torque required during the installation from which its holding power can be determined. This anchor has been throughly tested and when properly installed, provides far greater holding power than any other type of anchor.

Most yachtsmen are familiar with the tremendous holding power delivered by Danforth, Bruce, and especially CQR anchors which are used to secure a boat only temporarily. Granted, they are typically used with more scope then the average mooring system, but imagine with a storm on the way how well you would sleep if you could set your 45lb. CQR to a depth of 15 feet! In addition to its superior holding capability, another major advantage of the helix style anchor is that it is flush with the bottom leaving nothing to foul the chain. This allows your much needed scope to be there when you need it most.

Lastly, with all of the conventional style anchors, even if they do set themselves properly, they need time to do it, while the helix anchor delivers its superior holding power from the moment it is installed. For these reasons, I see a strong future for the helix anchor as the best possible solution to the problems that plague the conventional anchors.